Laboratory airflow control speciality design requirements

In any case, air should always flow from the effice, the corridor and auxiliary areas into the lab area. And all chemical laboratory exhaust gas should be directly discharged to the outside, and mustn’t be recycled. Therefore, unless chemical laboratory is required to clean itself, its relative to other space within a building maintains negative pressure of the camp.

Experiment indoor airflow should be from low risk areas to high risk areas. Generally speaking,it should keep the flow of gas 47 liters per second between the area(170 cubic meters per hour).Office areas in a laboratory should always maintain a positive pressure relative to the corridor and laboratory.

Under normal conditions, 6-12 times every hour’s room air changes are considered appropriate.When there is analysis equipment which is likely to produce high heat load or there is large local exhaust air in the room, there will be a beed to increase in volume.

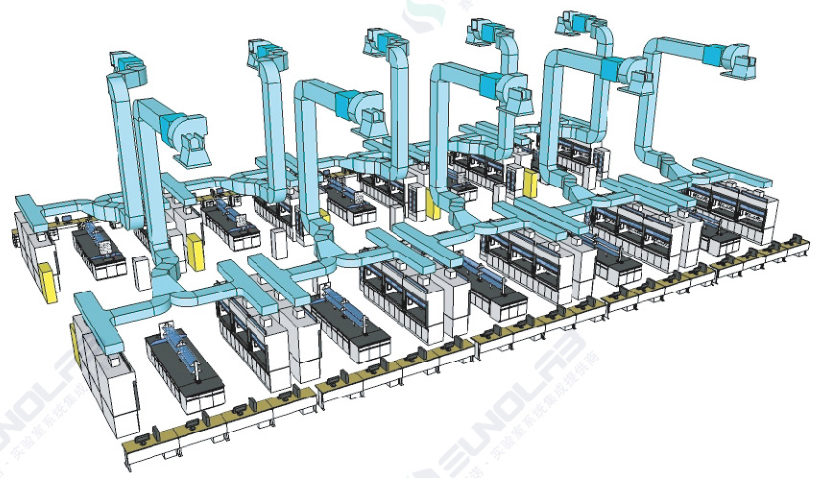

The laboratory should adopt 100% full fresh air system, the central air suppy unit and compensate laboratory exhaust demand.

In order to ensure the safety of the saff, keep the distance of discharge piont and flat roof at least 3 meters(ten feet) or even hgher in order to exhaust emissions and effectively diluted. The specific choice should be calculated to cofirm.

Interpretation of variable air volume speciality

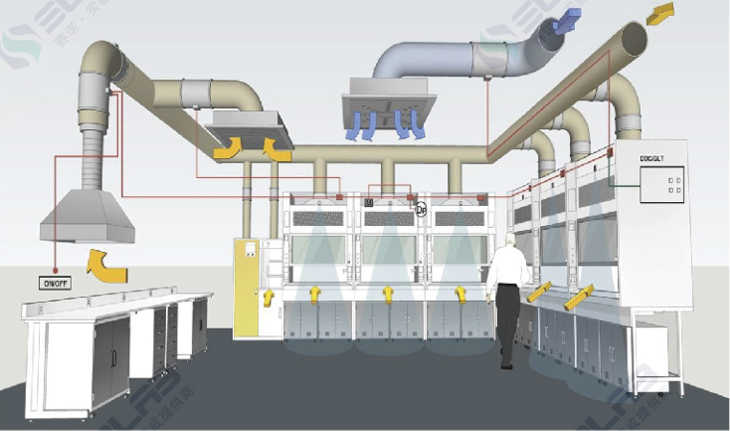

In the large ventilation system, in order to solve the ventilation equipment at the end of the variable air volume demands and comstant wind speed and to achieve further adjustment, we apply the frequency conversion and variable air volume ventilation control.

Laboratory airflow control aims

Security(Accord with the regulations and standards)

Local exhaust control

Regional pressure control

Energy-saving

Easy to maintenance and management

Availlability and flexibility

Adaptive control(Temperature and humidity)

Variable air volume control ventilation:Every country has strict requirements of the ventilation cabinet winds,For laboratory ventilation cabinet is the most important level of protective equipment.Generally we should always maintainconstant ventilation counter windspeed of 0.5m/s.Too high or too low surface windspeed can produce dangerous side leakage.

Local exhaust control: Cover cabinet, atomic absorption, reagent cabinets and some other local exhaust control should be able to continuously and effectively control and discharge the exhaust gases quickly and securely.

Room pressure control:Generally we should maintain negative pressure of the laboratory relative to that of the corridor in order to avoid cross contamination of the office or production areas.

Reduce energy consumption:On the premise of safety, significantly reduce energy consumption, including air conditioning and fan energy consumption.

The working principle of ventilation counter windspeed control system

1、Surface windspeed control system continuously monitors the actual exhaust air volume of the fume cabinet.Calculate the average windspeed of the open area according to the height of the window.When the exhaust pipe pressure changes or the window height changes, the system responses within a second and adjust the opening of the air valve to keep the average surface windspeed of the window open surfaces table

2、Under diferent experimental conditions, we can set different parameters on the panel.

3、The system controls surface windspeed at a set speed(0.5m/s) through infrared detector when there is an operator in front of the ventilation cabinet and the system automatically switches to another value(e.g.0.3m/s) to save costs when there is no operator in front of the fume cabinet.

4、When ventilation cupboard door was off, the air valve maintains the minimum of the ventilation cabinet exhaust air1500MM, the ventilation cabinet 300CMH.

5、Due to the fault surface windspeed is high or low, there will be sound-light alarms.

6、When temperatures of ventilation cabinet are high, there will be sound-light alarms.

7、When the position of the vent lation cabinet is too high, there wil be sound-light alarms.

8、When there is an exception, open the emergency discharge mode control and the system wil open all the air valves.Themaximum air volume of the ventilation cabinets is free from the control of the windspeed value.

We provide laboratory for variable air volume systems CON-LAB C with VAV fume hood control system CON-FHC, using the world’s most advanced VAV solutions through a digital controller for laboratory supply and exhaust, fume hood face velocity for strict monitoring and control.

Security no matter howto adjust the opening window, you can always precise control of the fume hood windspeed of0.5m/s+20%of imports.At the sametime the exhaust valve airflow tracking changes in the amount of wind to send theair valve to increase or decrease exhaust volume to ensure that the design of the infiltration airflow is constant, thusensuring a laboratory micro-negative pressure and airflow direction.System strong adapt ablity, and energyconsumptioncan be decline to fully protect the safety on this premise.

Importance of Laboratory VAV Controls

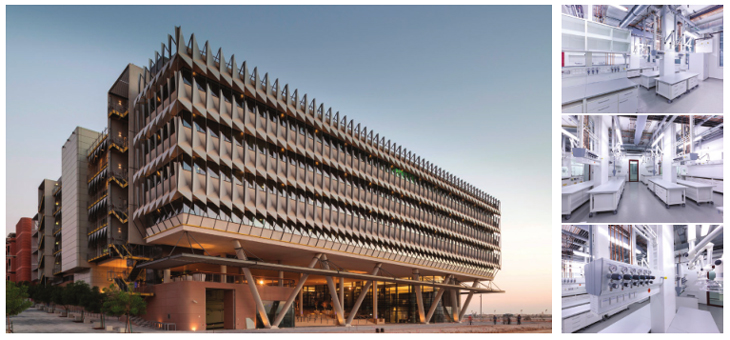

For the chemical laboratory, HVAC control is undoubtedly the most critical link. The safety, energy consumption, comfort, and ease of use of the laboratory all depend on the good design and implementation of the HVAC control system. We will find the most suitable solution for you based on your actual budget, construction period, building structure, usage requirements, maintenance requirements, etc.

Costing & Investment saving

Through reasonable design and planning, the use of a variable air volume system can not only greatly improve laboratory safety and reduce energy consumption after the project is put into use, but also at the initial investment stage, it can save money reasonably, even lower than the system design with a fixed air volume. The variable air volume system equipped with an automatic window module has raised a new level in terms of safety and energy saving.